This should probably fall into the ďtoo much time on my handsĒ category. But somebody might find it useful, so Iíll make it a little more visible.

Most of the time, aerosol (rattle-can) paint can instructions ask to you shake them from anywhere from one to two minutes. I donít know about you, but my patience runs thin after about ten seconds, so I often compromise on the shaking time. I recently started to use 2K aerosols. These ask you to shake for two minutes, then release the activator, then shake for another two minutes. My elbow is getting sore!

As a result, I decided to make a paint-can shaker. The idea being to put a can in, and let it mix away while Iím doing the masking or finish sanding. And to mix it better than I would have manually done.

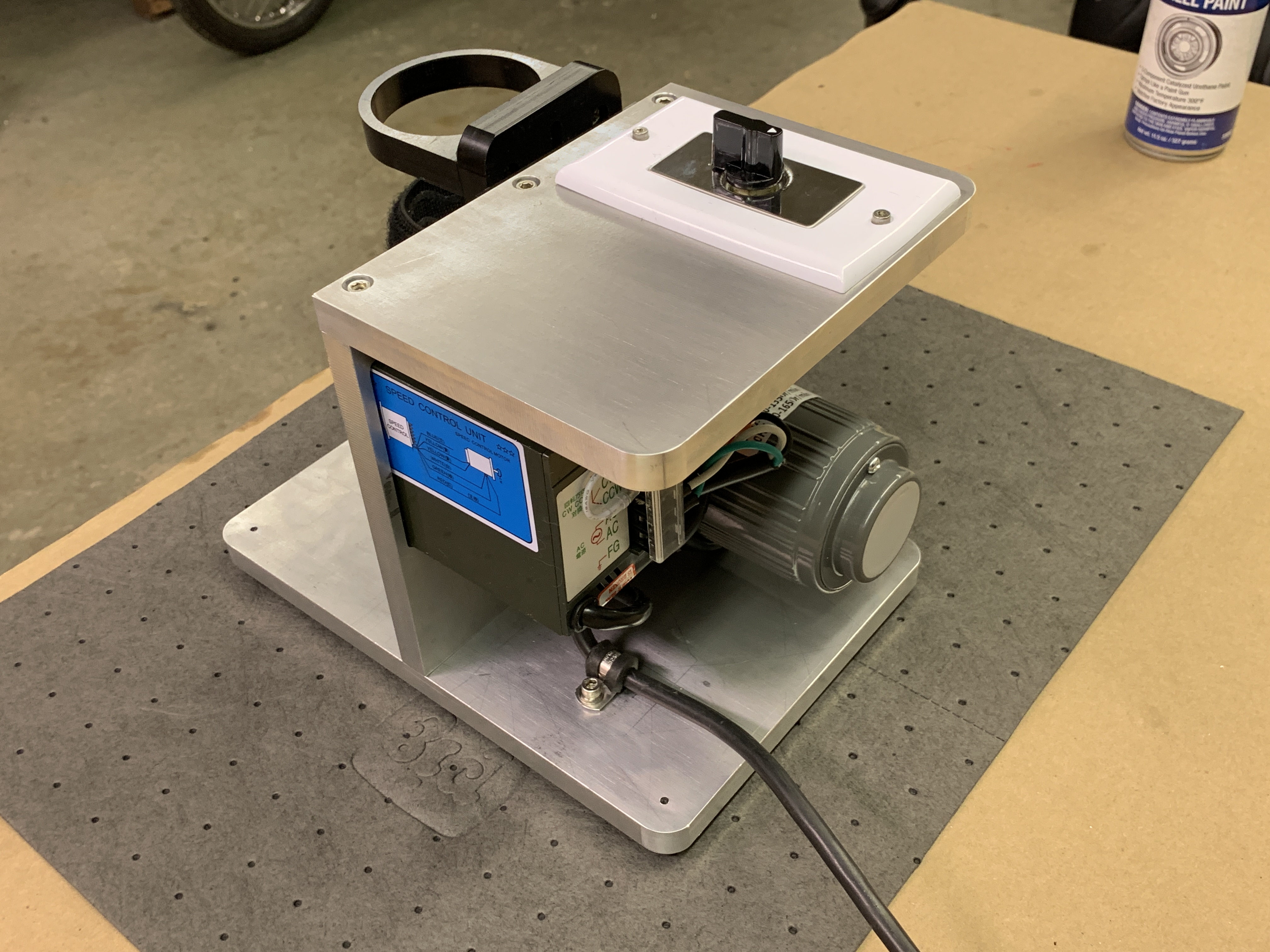

First step was to find a motor to spin a crankshaft. I shopped on eBay and found a new 120v motor and variable-speed switch assembly for $55 + tax (free shipping).

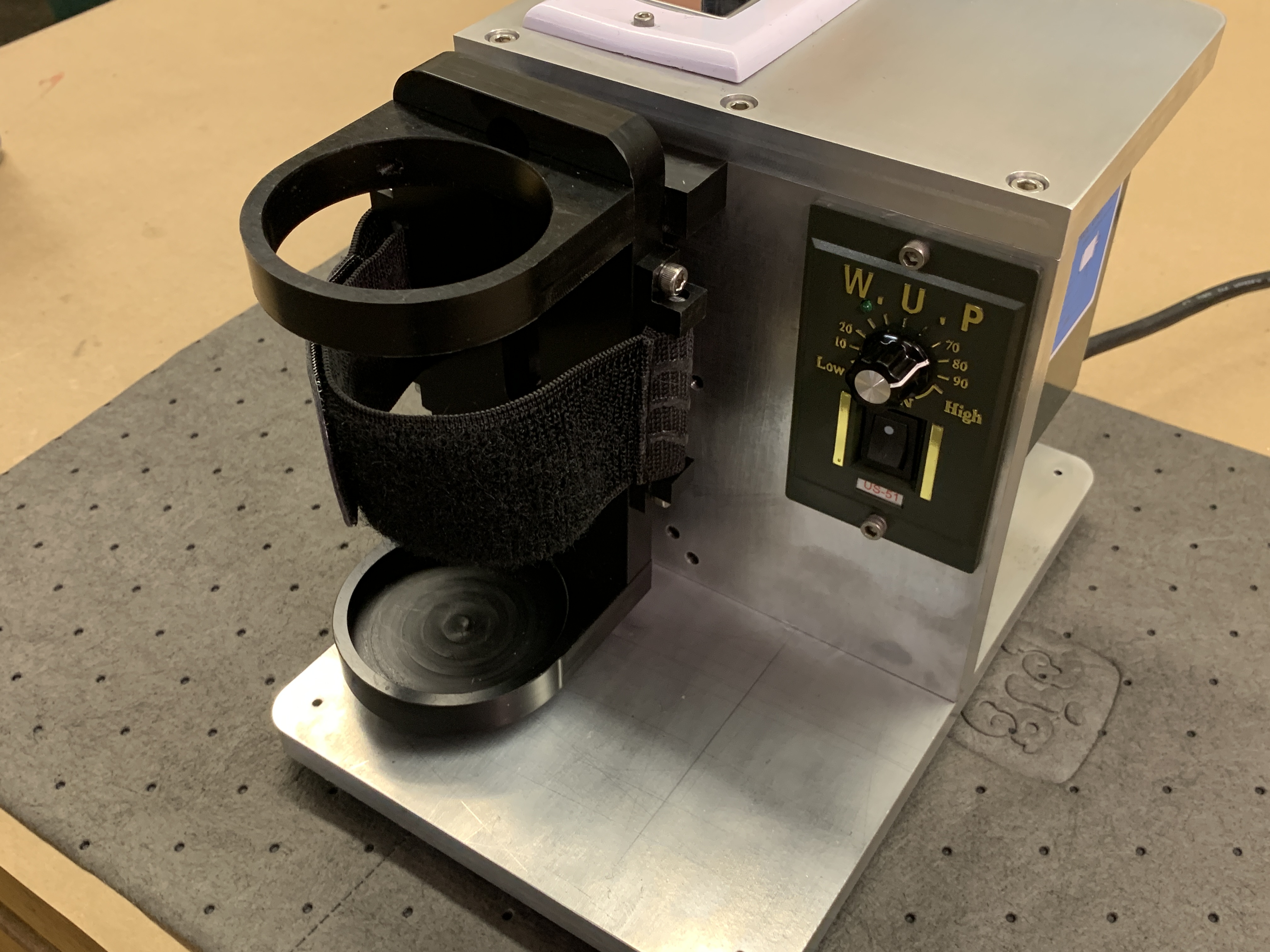

I decided to make the bottom of the can oscillate with a circle pattern of two-inch diameter. The top of the moving plate would slide up and down in a slot. Iíd use shoulder bolts rubbing against Delrin (Acetal) or Delrin-to-Delrin. Should be quiet, and last a long time. Plus, Iíve got some scraps of Delrin around, along with some ĹĒ aluminum plate. Donít need to buy much for this project.

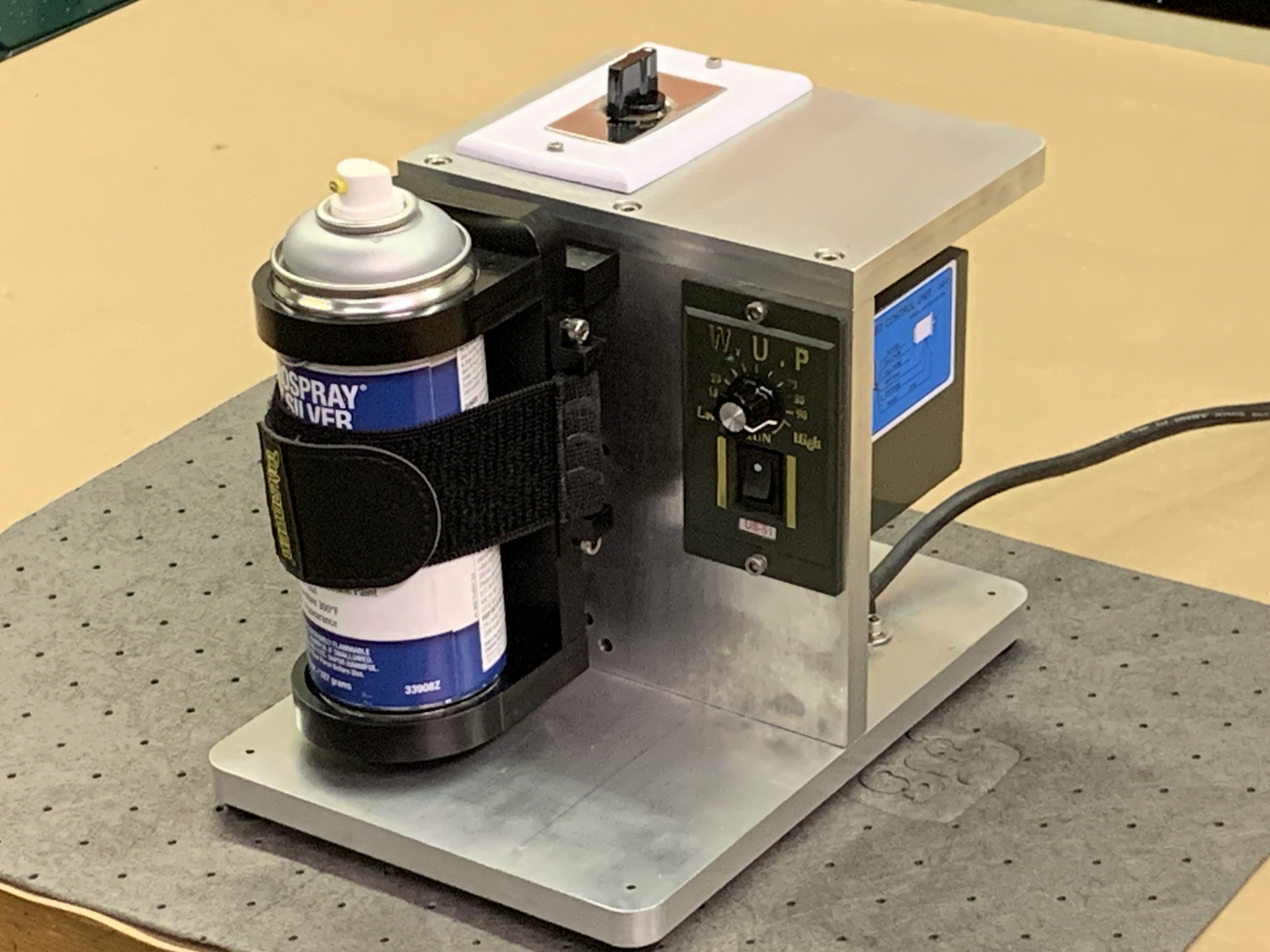

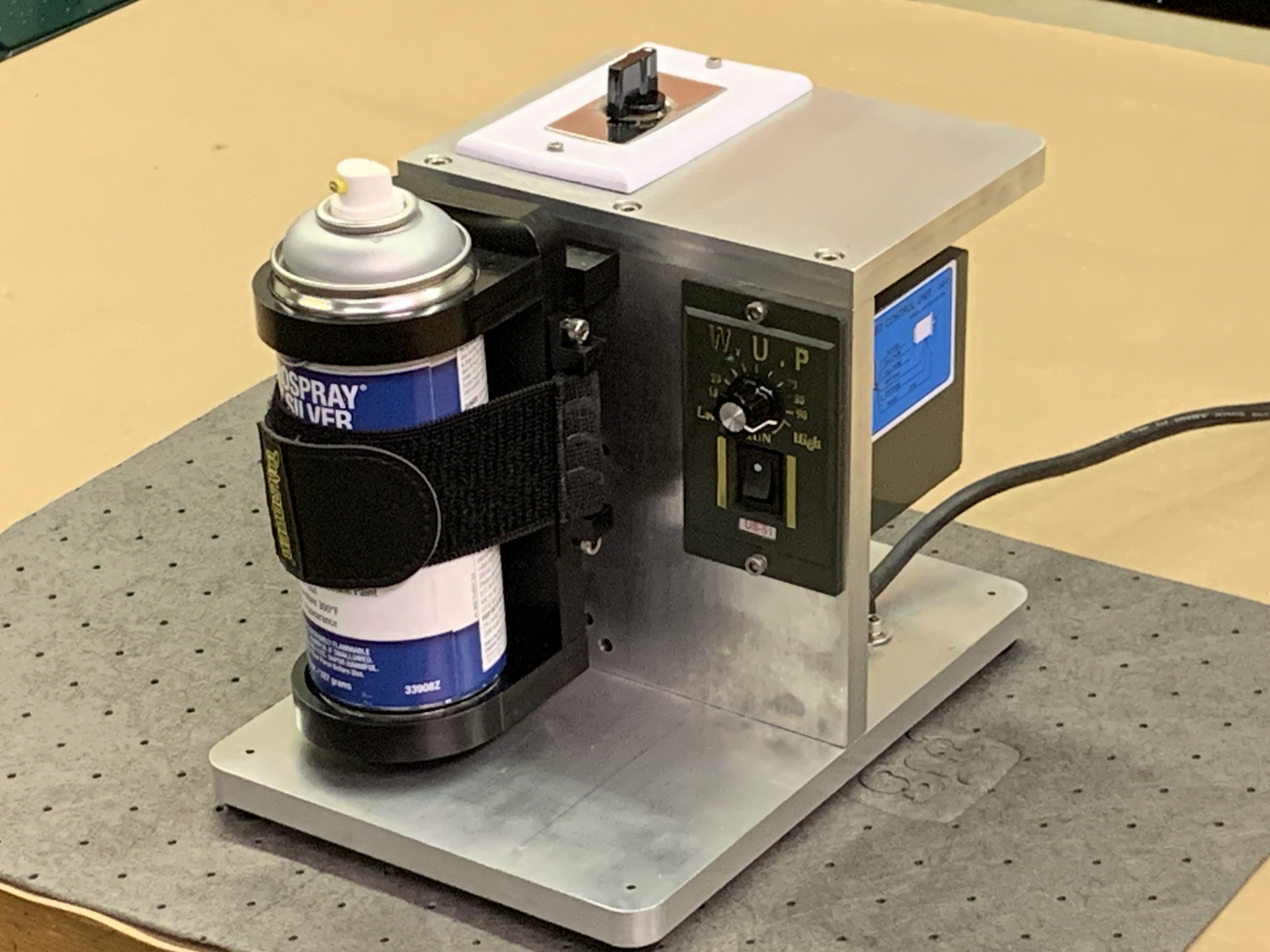

I needed a way to hold the can in place, even though it is supported top and bottom. I found a supplier of Velcro straps that are both elastic, and have some rubber ribbing on the inside, so they have some grip. This was the second purchase of the project.

So I set to work making drawings and making parts. Here are most of them (missing the top plate and with early short version of bottom plate)Ö

Here are a few views from different angles...

But, you ask, does it work?

It did take a little tweaking. The whole machine shook a little too much at first, indicating that a little more weight was needed. Also, I found that it would be nice to have a timer on it, so I could leave and not worry about it shaking forever. To solve both of these, I made the top plate with a timer. The timer was the third parts purchase - $15 - made for the heat lamp in your bathroom. I tried different oscillation diameters before settling in on this one. After these change, along with a few dimension tweaks to make it as smooth as possible, it works well!

A couple of people who have been in the shop while I'm using it have thought the can should be shaken on its side rather than verticle. Personally, I think it's fine either way, but you can lay it on its side if you want the other orientation. I don't shake cans manually sideways. However, the only other aerosol can shakers I've seen are attachments to connect the can to the end of a reciprocating saw (Sawsall). This would be a horizontal shake.

I used to design some machines before I retired, and it was nice to be free of all the safety concerns. OSHA would have a heart-attack with the pinch zone under the shaker. I did do a test and stuck my hand into that space and the machine stopped without drawing blood though.

If anyone wants to make their own personal paint-shaker, shoot me an email and maybe I can provide some drawings to help.

PS - I don't know what W.U.P. is on the face of the speed controller. It just came that way.